Sewage lift stations play a pivotal role in maintaining the flow of wastewater in commercial facilities, ensuring that sewage is transported from lower areas to higher elevations, where it can continue its journey to treatment plants. However, like any complex system, sewage lift stations are prone to malfunction if not properly maintained. Routine care and attention are essential to prevent costly repairs, reduce downtime, and avoid disruptions in service. In this blog, we will discuss essential tips to ensure your commercial sewage lift station in Dubai operates efficiently and reliably, keeping your business running smoothly and avoiding costly issues.

1. Regularly Inspect and Maintain Pumps

Pumps are the heart of any sewage lift station, as they are responsible for moving the sewage from lower to higher points. Over time, pumps can wear down due to constant use, leading to reduced efficiency or complete failure. To keep your system in peak condition, schedule regular inspections and maintenance for the pumps. Look for signs of wear, unusual noises, or vibration during operation. Make sure that the pump’s impellers, bearings, and seals are functioning properly and free from debris. Clean the pump and remove any build-up, such as grease, sludge, or solids that could impede its operation. Consider implementing a pump monitoring system that provides real-time data on the pump’s performance, allowing for early detection of issues before they become severe.

2. Clean and Remove Debris

Debris is one of the most common causes of lift station malfunctions. Items like wipes, rags, plastics, and grease can clog the pumps, floats, or valves, disrupting the flow of sewage. It’s essential to develop a regular cleaning schedule for the lift station, particularly the wet well, where sewage accumulates before being pumped. This includes removing any solids, fats, oils, or grease that could build up over time and compromise the system’s efficiency. Use proper tools and safety equipment when performing cleaning tasks and ensure that all waste materials are disposed of in accordance with local environmental regulations.

3. Monitor and Maintain Float Switches

Float switches are responsible for detecting the water level in the wet well and activating the pumps when the level rises. If these switches malfunction, the pumps may not turn on or off at the appropriate times, leading to overflows or dry runs (when the pump runs without water). Regularly test the float switches to ensure they are functioning correctly. Adjust them if necessary to maintain proper water level thresholds and prevent unnecessary wear on the pumps. Check for any signs of damage, corrosion, or buildup around the float switch area that could cause false readings.

4. Implement Alarm and Monitoring Systems

A reliable alarm and monitoring system is vital to prevent unexpected failures in your commercial sewage lift station. These systems can alert you to potential issues such as high water levels, pump malfunctions, or power failures, allowing for quick intervention before the problem escalates. Consider installing remote monitoring systems that provide real-time updates on the lift station’s performance, which can help detect issues at the earliest stages. Regularly test the alarm system to ensure that it works as intended and is audible or visible to relevant staff members, even during off-hours.

5. Perform Routine Preventative Maintenance

Preventative maintenance is key to ensuring the long-term functionality of a sewage lift station. Create a maintenance schedule that includes checking key components, such as the pump, floats, alarm systems, and check valves, on a regular basis. Keep a log of all inspections, maintenance tasks, and repairs to track the system’s performance over time and identify potential areas of concern. Preventative maintenance may also include lubricating moving parts, tightening bolts and seals, and replacing worn-out parts before they cause a failure. Proactive maintenance is much more cost-effective than dealing with an unexpected breakdown.

6. Ensure Proper Ventilation

Sewage lift stations often deal with unpleasant odors and potentially hazardous gases, such as methane, hydrogen sulfide, and ammonia. Adequate ventilation is essential for maintaining safe and healthy working conditions, as well as for the proper functioning of the lift station. Ensure that the station is equipped with proper ventilation systems, such as exhaust fans or vents, to allow for the dissipation of gases and odors. Regularly inspect the ventilation system for blockages or damage and clean it to ensure it remains effective. Poor ventilation can lead to the accumulation of harmful gases and increase the risk of corrosion within the lift station.

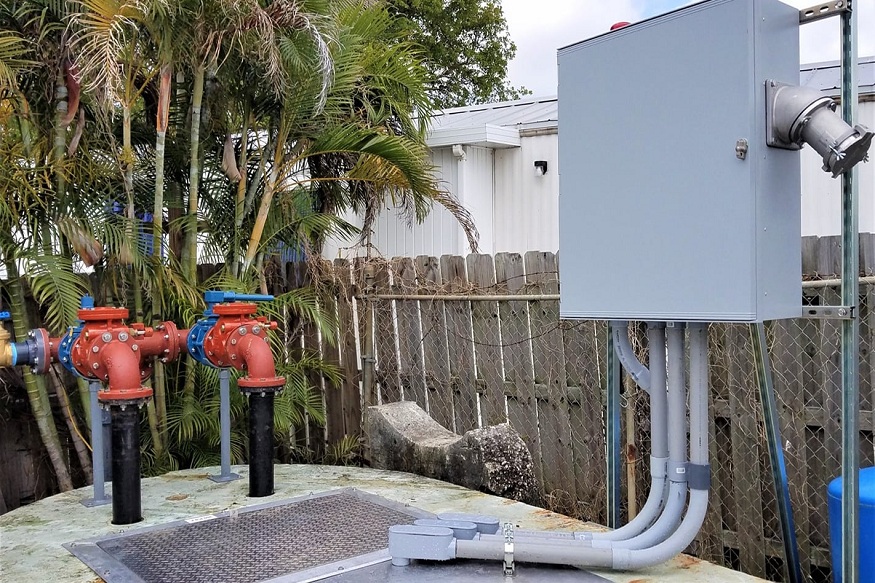

7. Perform Electrical and Power System Checks

A sewage lift station relies heavily on electrical components to function properly, including the pumps, alarm systems, and control panels. Regularly check the power supply, circuit breakers, and electrical connections to ensure there are no signs of wear, damage, or loose connections. Power surges or interruptions can cause the lift station to stop working, so consider installing surge protection devices and backup power systems, such as generators or battery backups, to prevent service disruptions. Periodically test the backup power system to ensure it’s fully functional in case of an emergency.

8. Ensure Proper Sizing and System Design

The design and sizing of the mini micro sewage pumping station are crucial for its long-term performance. A lift station that is too small or improperly designed can experience frequent issues such as pump failure, overflows, or increased wear on equipment. Ensure that the station is designed to handle the expected flow of sewage and has enough capacity to accommodate peak usage times. Work with an experienced engineer or consultant to review the lift station’s design, especially if your facility has expanded or its sewage output has changed. Retrofitting an underperforming system can help improve its overall efficiency and reduce the likelihood of breakdowns.

Proper maintenance of a commercial sewage lift station is critical to ensuring its long-term functionality, minimizing downtime, and avoiding costly repairs. Proactive care will not only improve the lifespan of the system but also contribute to a healthier and safer environment for everyone involved. Prioritize routine maintenance and invest in your sewage lift station today to avoid expensive disruptions tomorrow.